Manoeuvre Nr. 2 – Oil Tanker

- Oil tanker 300 meters long

- 14 meters draft on a depth of 15.5 meters

- Adequate engine, right-hand fixed pitch propeller and traditional rudder

- An ASD type tug (Azimuth Stern Drive), two Voith Schneiders and an Escort tug.

- The manoeuvre involves navigation in a section of the canal, turning clockwise in a basin of 450 meters in diameter, proceeding backwards and mooring on the port side alongside a quay.

We need to determine where to make fast the tugs and how to use them.

We know ASDs have two stern thrusters that can rotate 360 degrees, and they usually have two towing points, one positioned forward and one at the centre.

So they can work secured aft (bow/stern) or forward (bow/bow), or (stern/bow) in a conventional way.

We also know that they have a high risk of girting/capsizing when used aft.

The Voiths have two cycloidal thrusters in a forward position close to the centre and the towing point at the stern. As we have already mentioned, the tow point is towards the stern (usually at 0.1 / 0.2 x SWL). Thus, they work stern/bow forward and stern/stern aft. They also may work bow/stern using the fore winch, albeit, in this case, their propulsion may suffer the ship’s wake effect.

The risk of capsizing is low as they work well at high speeds, and having the thrusters far from the towing point, can easily control the interactions in the vessel’s proximity. Lateral movements are also accurate thanks to the position of the propellers to the Pivot Point.

The Escort tug has the winch positioned in the centre or aft on the “Tractors” and forwards on the “stern drives”. Their purpose is the transit assistance and manoeuvre of large ships.

Based on what we said above, we decided to make fast:

- The Voith secured forward from central Panama lead because less suffers from the ship’s bulbous bow interactions.

- The ASD forward secured at the starboard bow to take advantage of its power within the turning circle.

- The Escort tug towing on a line aft to the centre will serve both in case of emergency to slow down the speed or stop the vessel.

- Finally, the last tug, the second VSD to the port’s stern, towed on a line.

One of the most delicate aspects is the headway speed, which must always be adequate at every moment of the manoeuvre.

Phase 1

Canal. We use the time we take to pass through the stretch of the channel that precedes the entrance to decrease speed and make fast the tugs. In this case, we have a starboard curve to tackle before a short straight that allows us to set the correct alignment for entering the port. With heavy and oversized ships, it is reasonable to assume that it is necessary to use the engine to ensure good steering. For this reason, we will reduce the speed in the section preceding the turn; if we didn’t, we would find ourselves with a high speed to face the bend with the need to put the engine ahead to steer. The result would be an excessive headway at the port entrance.

So, purely by way of example, we arrive at the beginning of the canal with the engine dead slow ahead and a ship’s speed of 6 knots. We stop the engine and proceed with only the residual speed, using engine kicks to maintain steering if necessary.

Here we find the tugs waiting for us. We’ll go to secure the Escort tug first to the aft centre lead to make it ready to work in case of an emergency. The second tug will be secured forward from central Panama lead; the reason is technical: some inconvenience can always happen when you make fast a tugboat (the messenger breaks, the line works poorly, the crew wastes time, etc.), and you could find yourself reaching the entrance with the second tug not still fastened.

If we manage to secure the one at the fwd centre, it can help us bend to the port. Still, if, on the contrary, we made fast the one to fwd starboard and the crew is working to secure the one in the fwd centre, the starboard one will not help us bend because hampered by the engagement of the centre tug. In practice, we would find ourselves unable to use the forward tugs. Furthermore, at this stage, the situation would get worse if we needed to give astern with the engine: the paddle-wheel effect could be difficult to control with the only stern tug, especially on a heavy ship.

Then we’ll go to make fast the last two tugs, the Voith aft to the port quarter and the ASD forward on the starboard.

We face the canal’s curve with the engine dead slow ahead that we stop as soon as the bow is correctly aligned for the entrance. We arrange to have a speed of 4 knots at the curve exit and 3 knots at the port entrance.

Suppose we get too fast at the entrance. In that case, we can reduce the velocity inviting the ship to the port and then go astern with the engine to counteract the paddle-wheel effect, which is rather accentuated in these conditions.

Phase 2

We are now with the ship in the outer port, the stern beyond the entrance.

We proceed losing speed until the forward half of the ship’s hull is free of obstructions on its port side, then we put the two aft tugs to work to port (you can follow the manoeuvre in the video above). The one secured to the port works sideways, while the Escort, working at 45 degrees, also has a braking component that comes in handy.

The speed continues to decrease until it reaches about one knot, when the bow begins to fall due to the rotation of the stern. The Voith positions itself to the port to counteract the swinging of the bow while the stern continues to rise. At this point, a Dead Slow Astern engine kick is usually required, which on this type of ship does not have a massive braking effect but give us feedback to make sure that the engine has started, ready to be increased if required.

Before completing the turning, we move the Escort tug to starboard, ready to slow down lateral movement and let go of the stern port tug to position it to starboard aft, ‘ready to push’. Also forward, we let go of the port tugboat, moving at the starboard bow, ready to push the vessel alongside.

Phase 3

Soon, we were close to zero speed, and the ship lined up to move back towards the mooring. Two tugs are towing on a line, one on the centre-bow and one on the centre-stern, ready to widen, and two operating on starboard side pushing to accompany the ship alongside.

Here, too, we adjust the headway to make sure we stop the ship whenever we want.

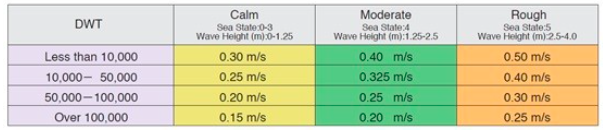

We are, therefore, at a certain distance from the final mooring position, parallel to the quay. It is essential to know that many accidents occur due to excessive lateral speed precisely at this stage. It is necessary to operate for parallel docking, without approach angles, to evenly distribute the ship’s weight on as many fenders as possible.

Below is a table extracted from the “Yokohama Pneumatic fender Guidelines“, which indicates, for different vessel’s DWT for each weather condition, the velocity to maintain approaching the quay:

To manage the vessel behaviour we are manoeuvring isn’t simple, but the correct use of the tugs make it possible to guarantee the mooring operation in safety. Two tugboats to pull and two pushings allow precise lateral movement control provided that – given the mass of the ship and the relative inertia involved – actions are taken in time.

It is the opportunity to define the “kick ahead or astern”:

The “kick ahead” is used to maintain a straight direction or start turning when the ship has a minimum speed such that the rudder is not efficient. We have to put the engine ahead decisively for a short time to significantly increase water flow on the rudder but without causing an increase in speed. We must stop the machine before lateral inertia becomes less effective than the tendency to accelerate. Before proceeding with the “kick”, we need to put the rudder hard over on one side. If we used a slight rudder angle, much of the propeller’s flow would undesirably increase the ship’s velocity. For the same reason, it is crucial to stop the engine before recovering the rudder amidship.

In our case, we can use the “kick” to slow down or increase the stern swinging, to reach the desired position, or stop the ship.